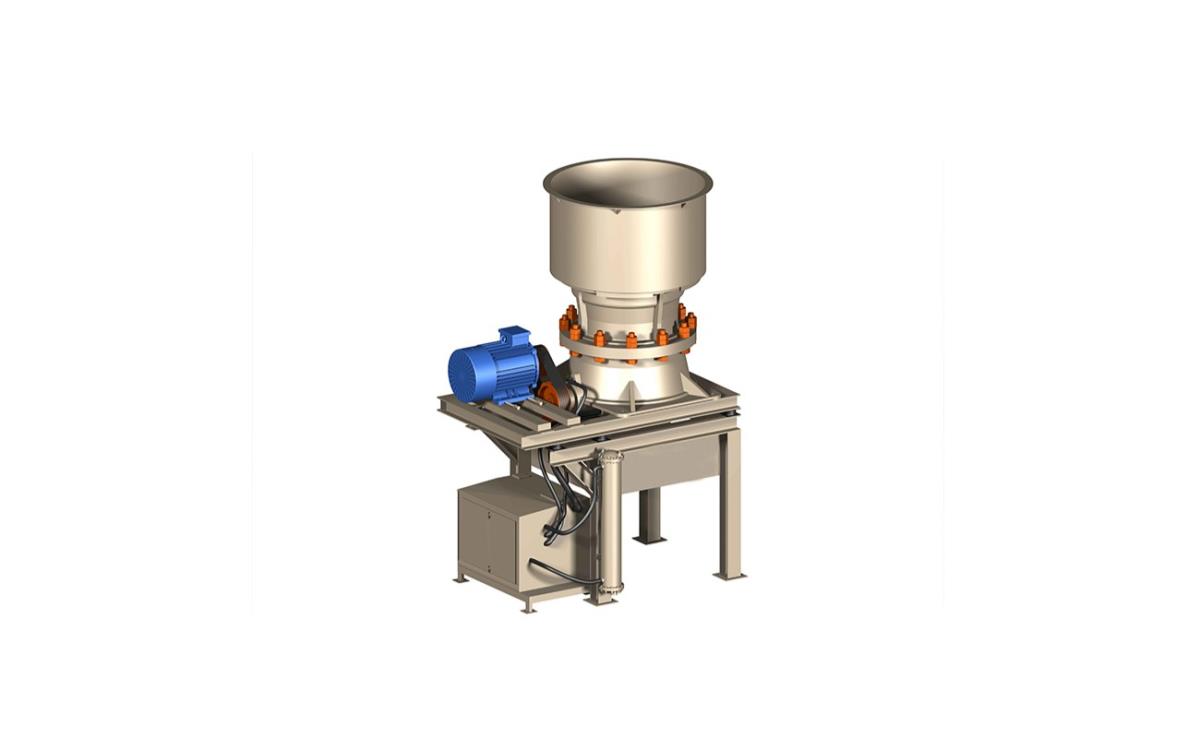

Hydrocan Cone Crusher

Model

Capacities

13-36

100-200

8-36

80-90

7-36

70-80

5.5-36

55-65

4-36

45-60

2-36

40-50

Hydrocan Cone Crusher

Hydrocan Cone Crusher

This kind of crusher is used in middle stages of crushing and is specially designed for hard stones such as iron ore. Cone crusher is a secondary crusher in sand washing line in which the crushing is done by closing the gap of mental by the eccentric which is in the bottom of the shaft and make it rotate. The size of output product can be adjusted by changing the size of input mental by a lifting jack. Also the speed of moving materials and size of output product can be changed by adjusting the size of eccentric. All the parts of the machinery which are in contact with the input materials and stones are made from molybdenum manganese steel which has high resistance.

Cone crusher is installed by a hydraulic oil tank and a cooler on its chassis. The input opening of this crusher can change from automatic to manual and is used for controlling the function of the machinery. These crushers are equipped to special radiators for oil which are suitable for mines and sand washing lines that are installed in hot and dry weather. Hydrocan Cone Crushers are manufactured in different sizes of 2-36, 4-36, 5-36, 5.5-3, 5.6-36, 8-3 which are used for breaking small, medium and big stones.

Features and characteristics of Cone Crusher

Used as primary and secondary crusher in mines

Fast closing of the input opening by the hydrost for preventing erosion and controlling the size of output products

High efficiency in crushing hard stones

Designing different kinds of input and feeding opening from 1to 8 inch

Suitable for high production of sand

Equipped to penion spiral gear which is silent and has long life

High capacity because of big input opening

Rowing used in penion shaft has long life and low maintanence cost and because of being integrated can be repaired without disarring the machinary

Strong building and high resistance of the machinery

Equipped to small and medium input openings ,including two and three spider arms

Long life of manganese parts of inside the crusher because of same thickness and suitable reliance point

Equipped to dust catcher of oil pretection, made from threaded fiber for protecting the parts of crusher from dust

Correct selection ofeccentricity for controling the size of materials bigger than needed among the avaiable standard

Equipped to the tank with energy regulator

Cover of bottom shell made from anti-wear manganese steel

Fast discharge of the body because of decomposition made in the design of the botom shell

Abrasive parts made from molybdenum manganese steel

High efficiency and low maintanace cost becase of 3 automatic lubrication system